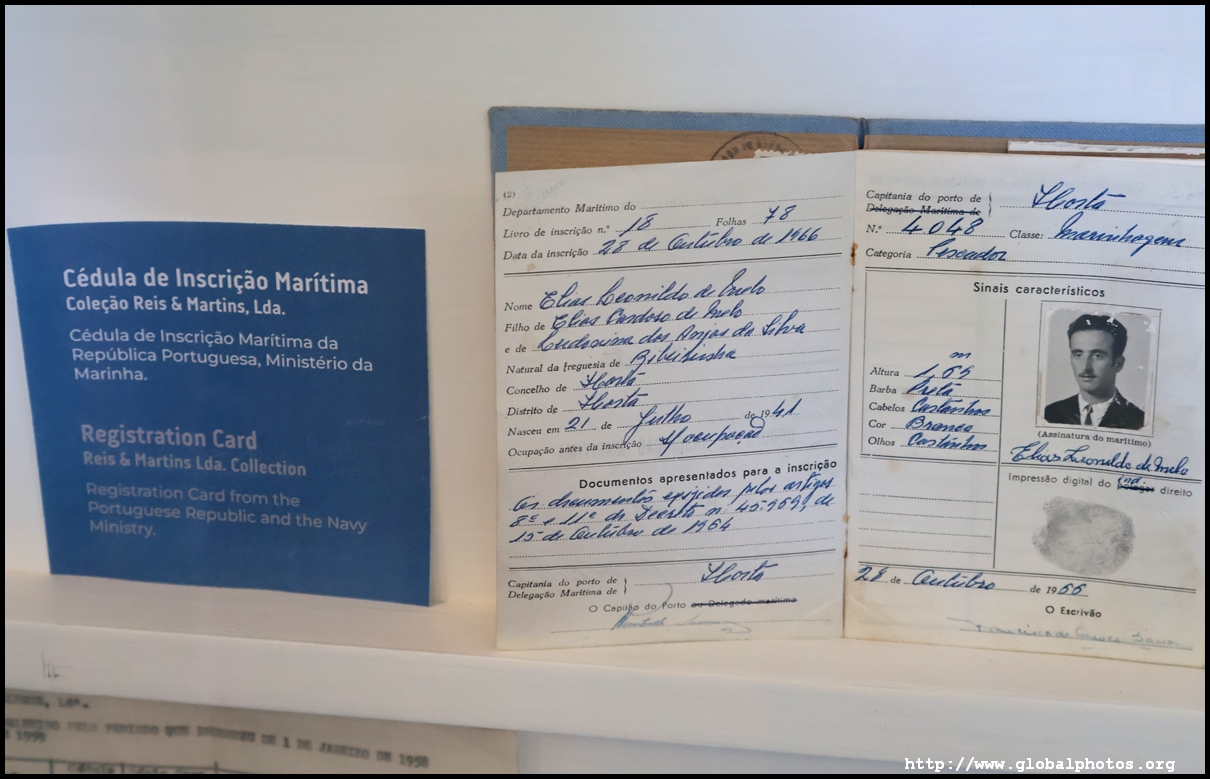

Just a short walk from the marina is Porto Pim, a protected bay that was home to a whale processing factory that produced oil for export. Whaling was a huge industry in the Azores long ago, with sperm whales caught in area waters to be processed with advanced imported machinery in this factory.

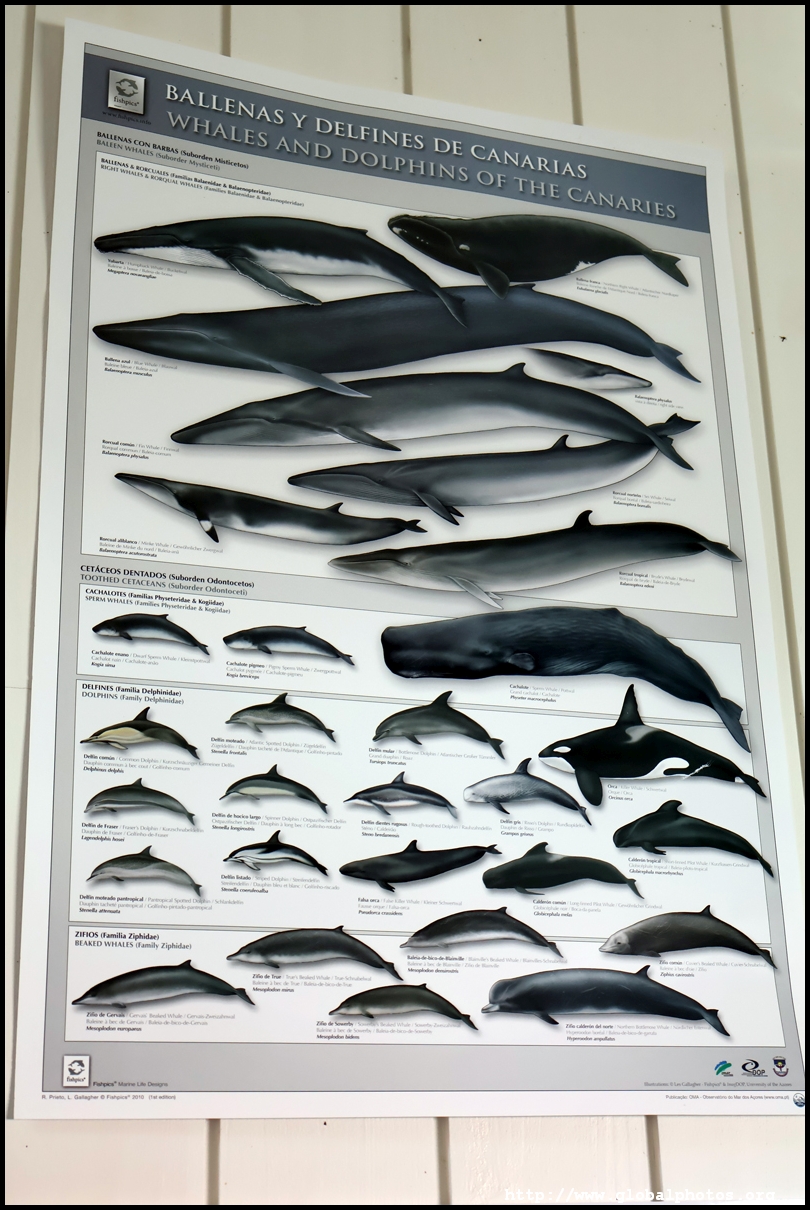

The English name for sperm whale was given when the first people that opened the whale's head saw oil inside and thought it was the creature's sperm.

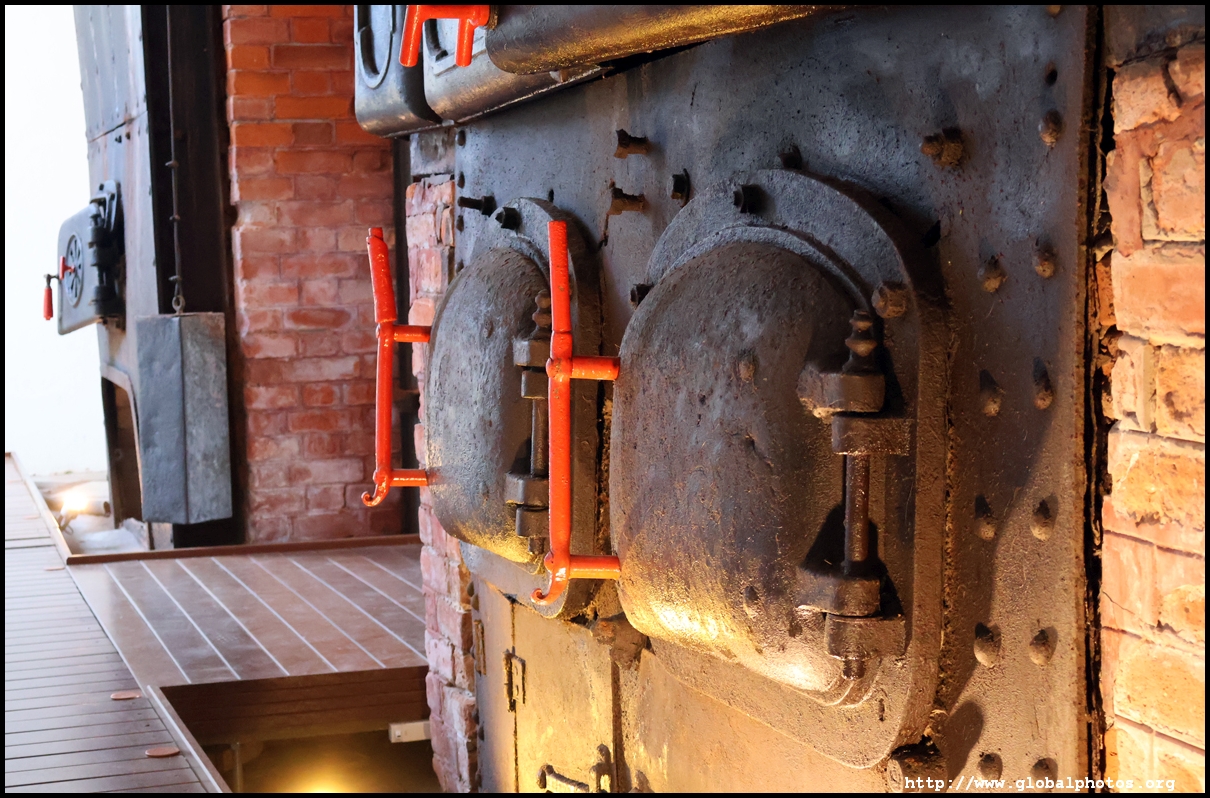

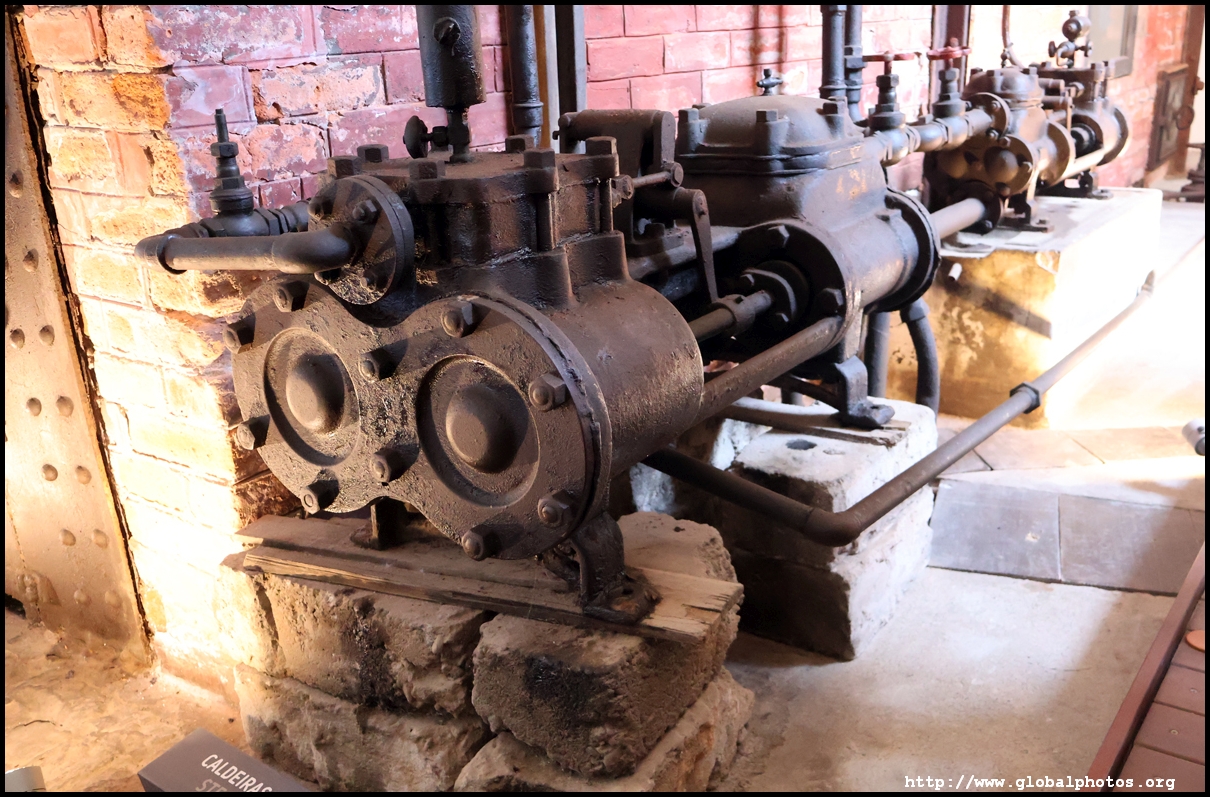

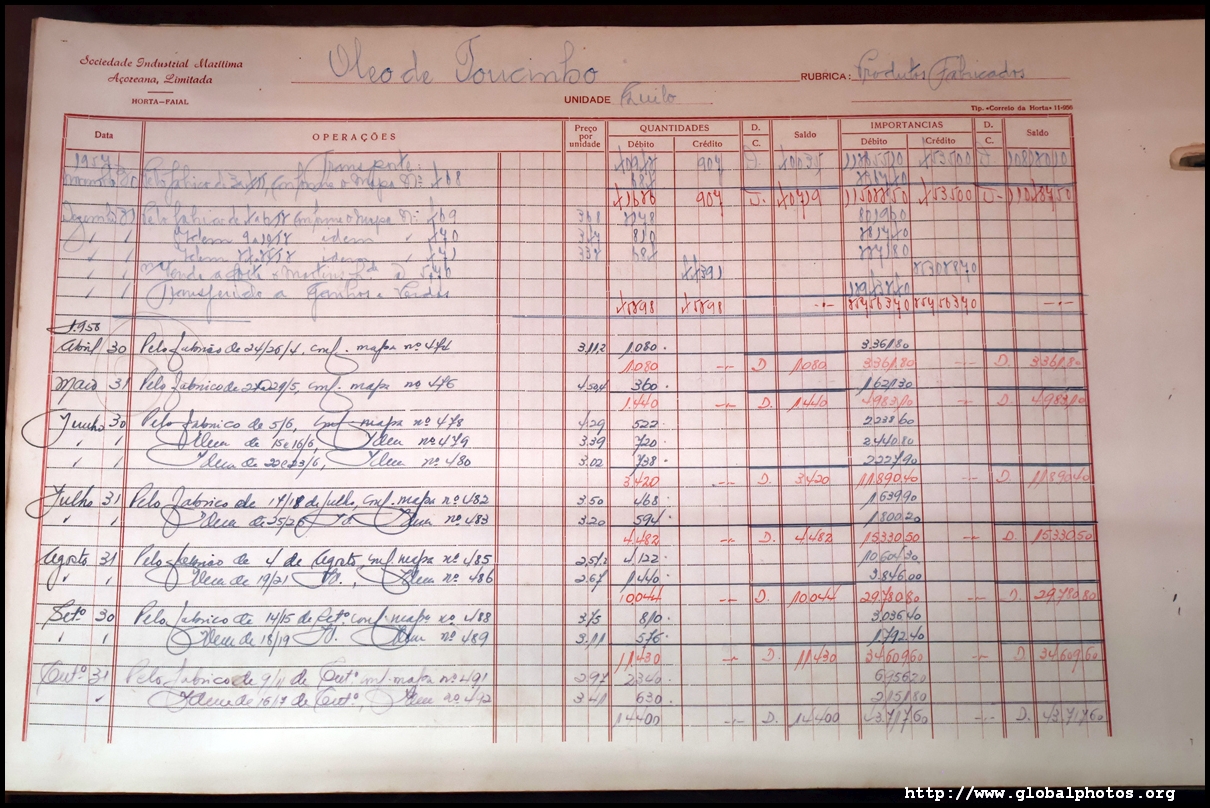

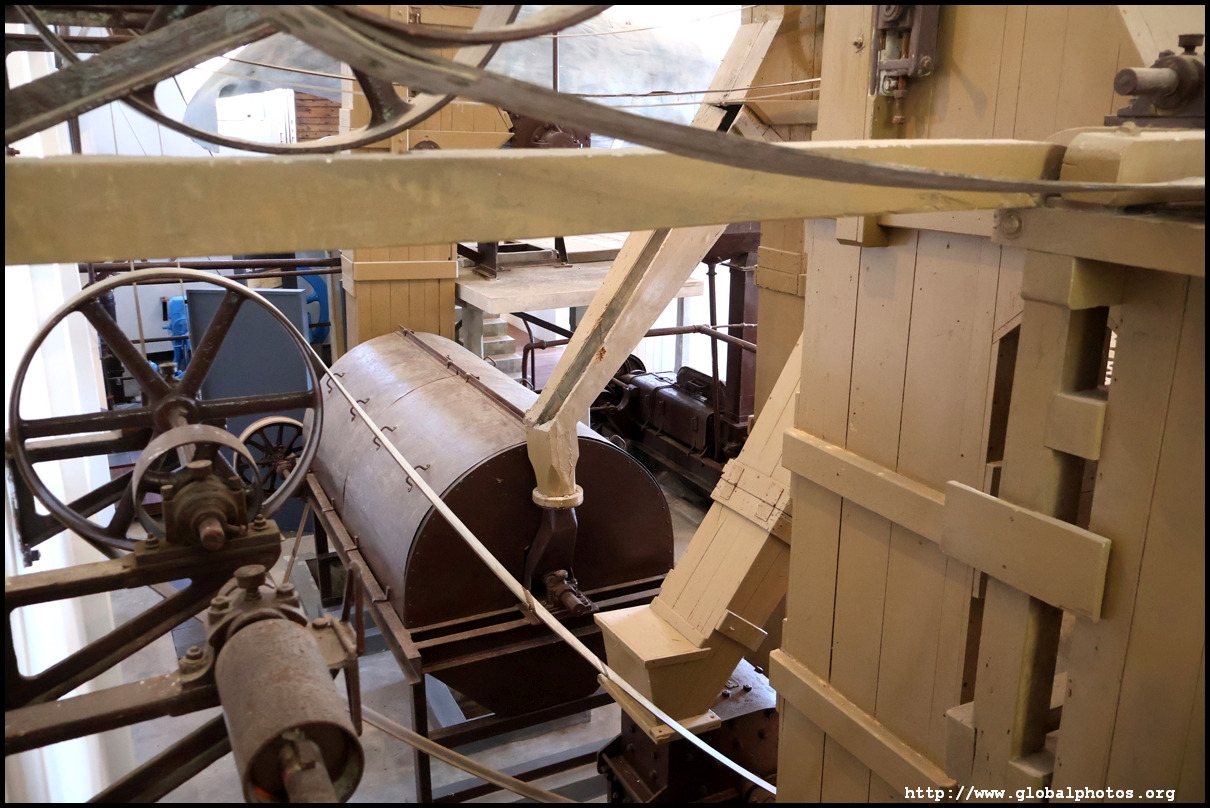

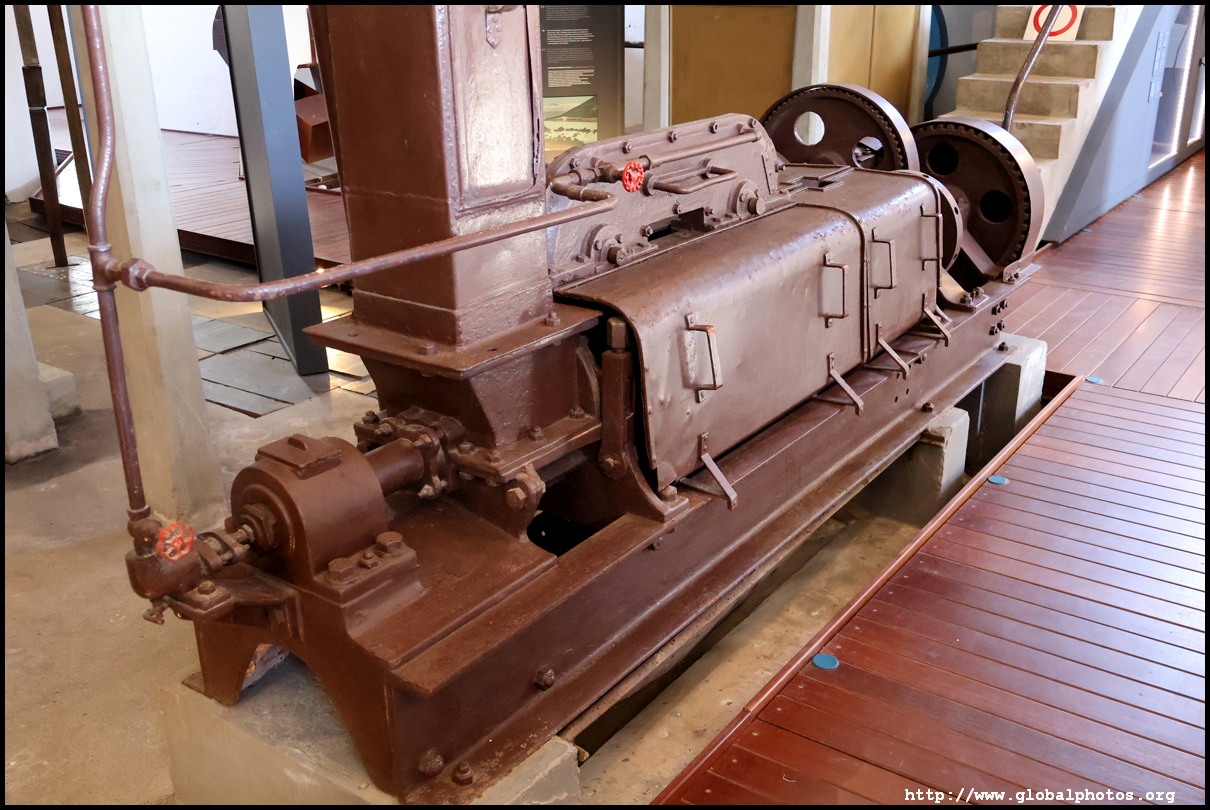

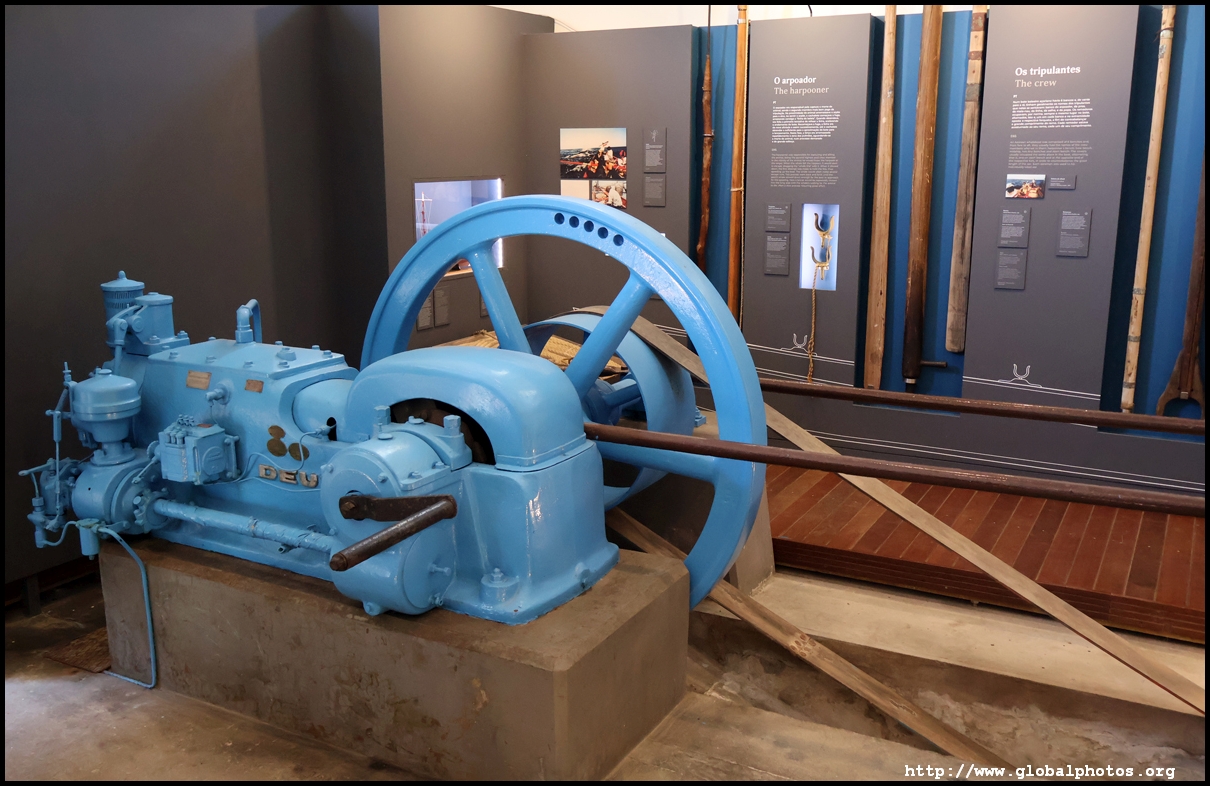

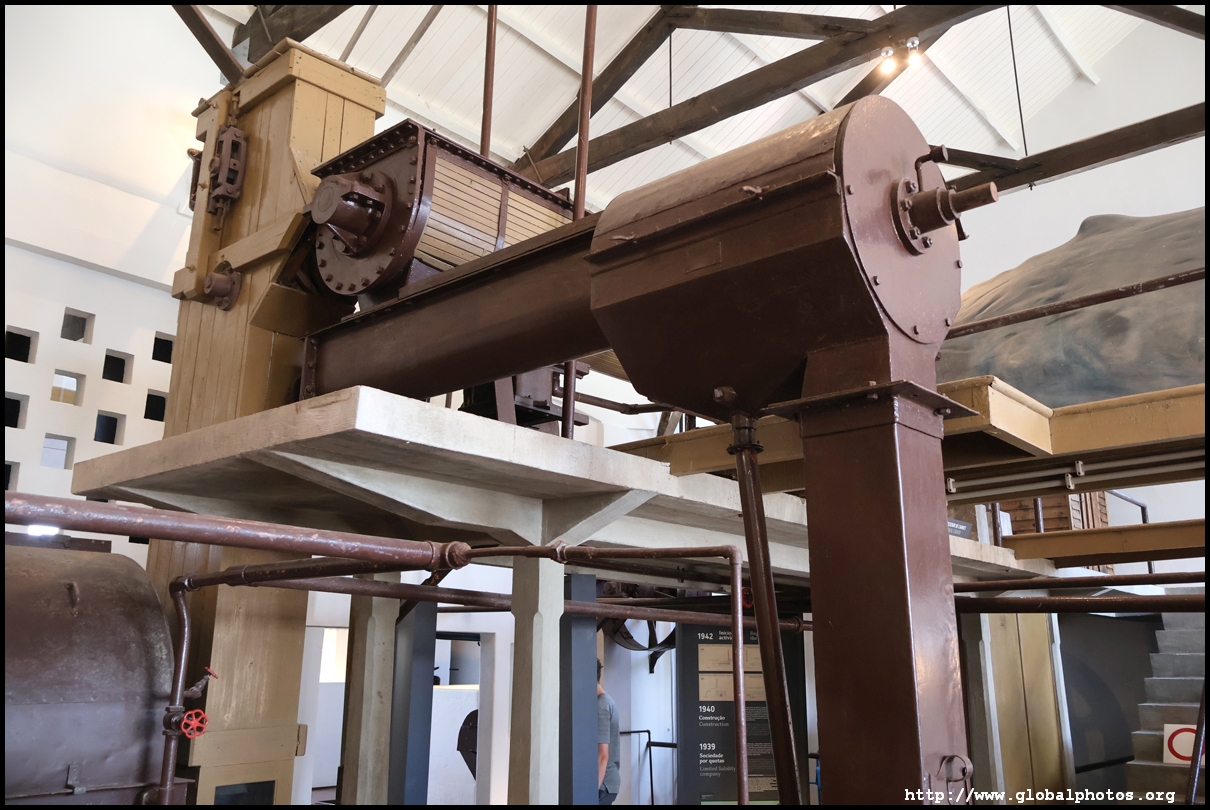

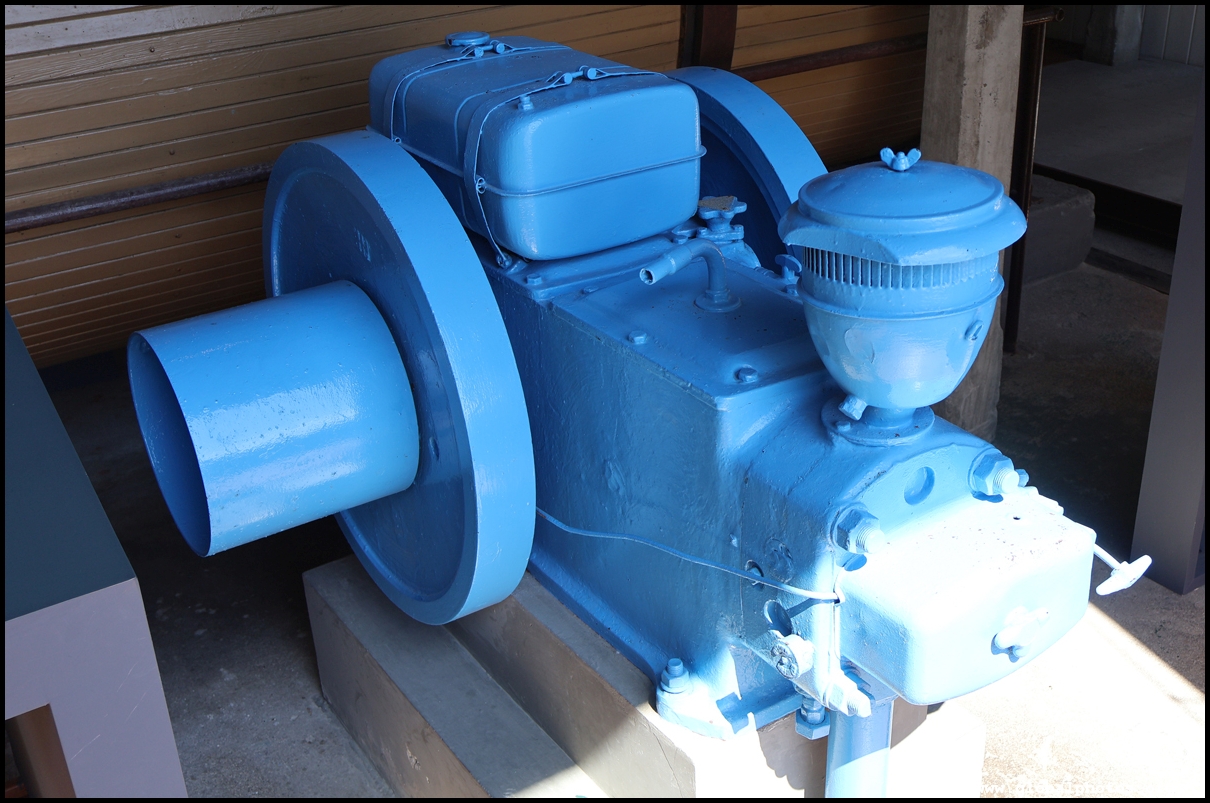

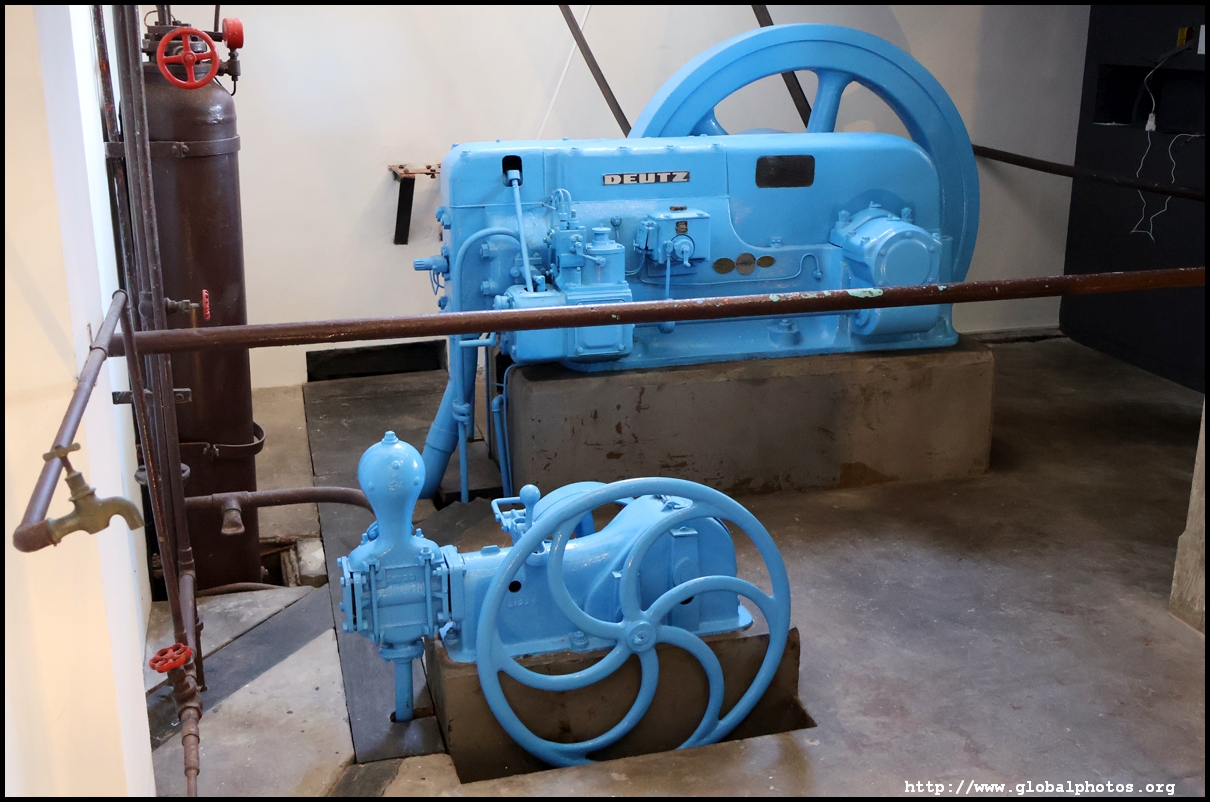

The factory was powered by steam and operated for 30 years until 1974, producing 44,000 barrels of oil in total. The oil was good fuel for lamps and industrial applications, such as machinery lubricant, paint drier, and leather tanning. Until the 1940s, oil was the only product from the Azores' whaling industry. This factory made it possilble to use the meat, bones, and blood as well.

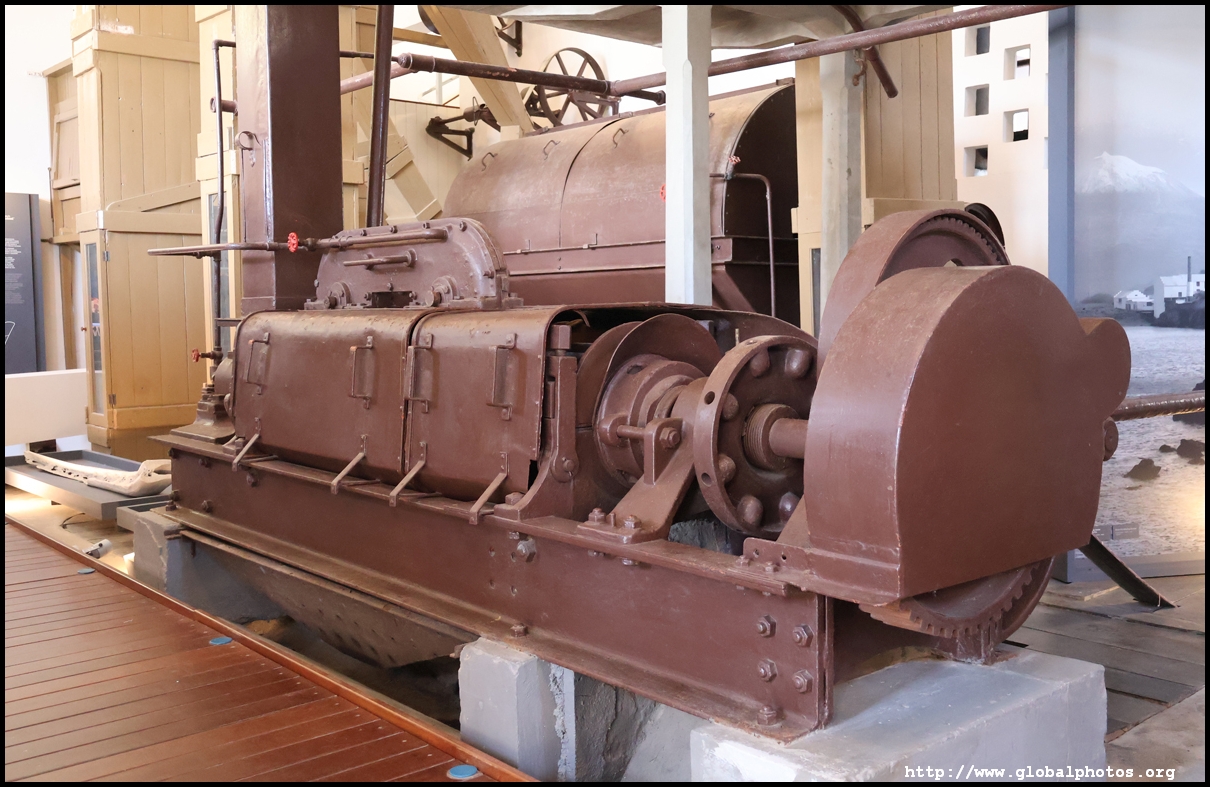

After the factory closed and many years later, the building has turned into a museum, with the equipment laid out so we can understand how the whale is processed into products for export.

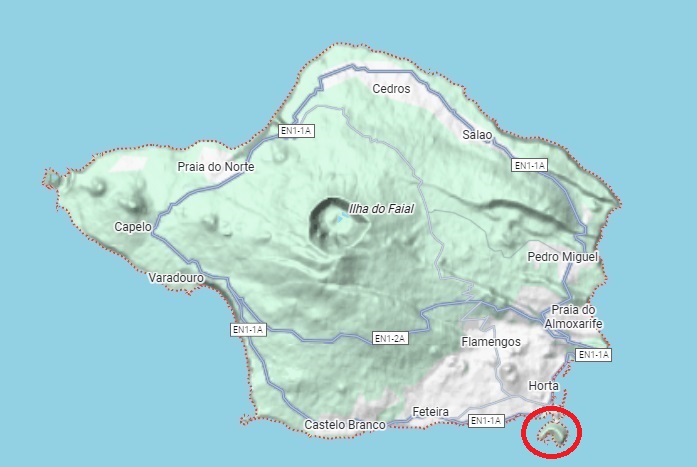

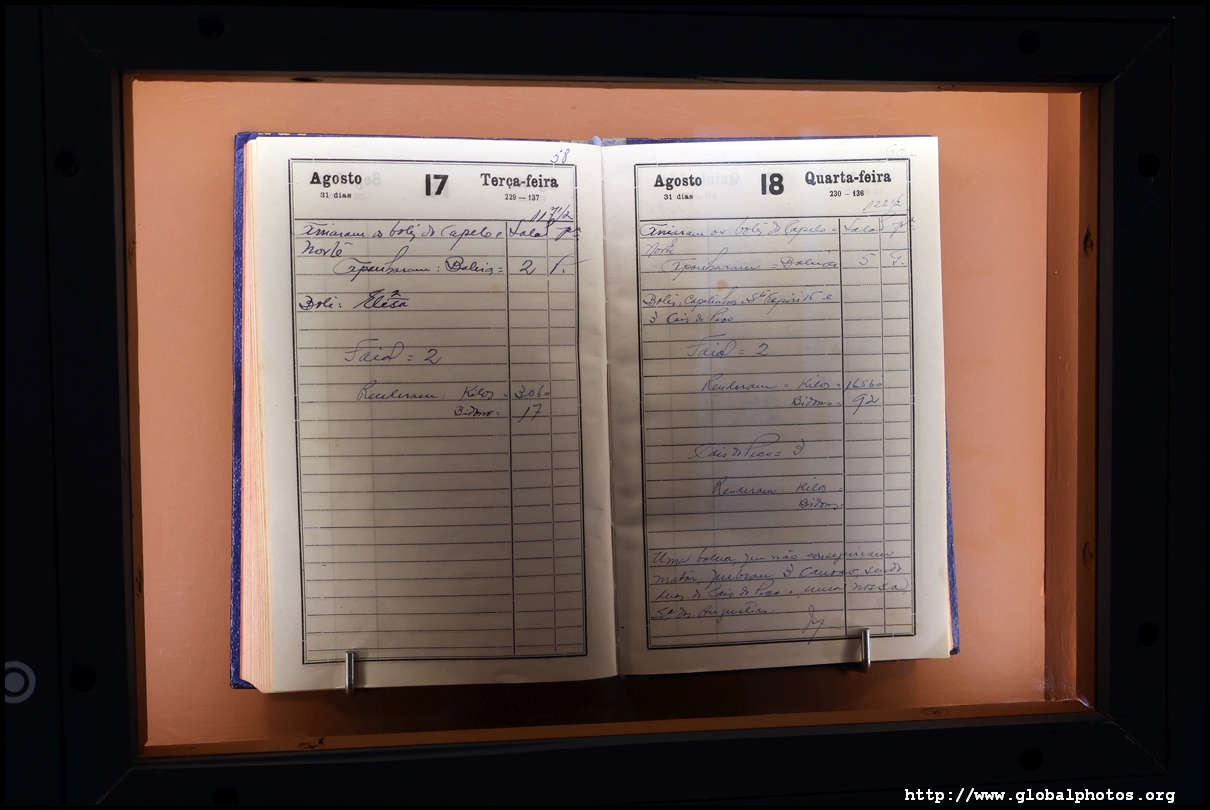

The whaling process begins at the lookout, where spotters searched for signs of whales in the water. They sat on benches or stools and used binoculars to scan the ocean. A firework was launched upon sighting to alert sailors to get into the water for the hunt.

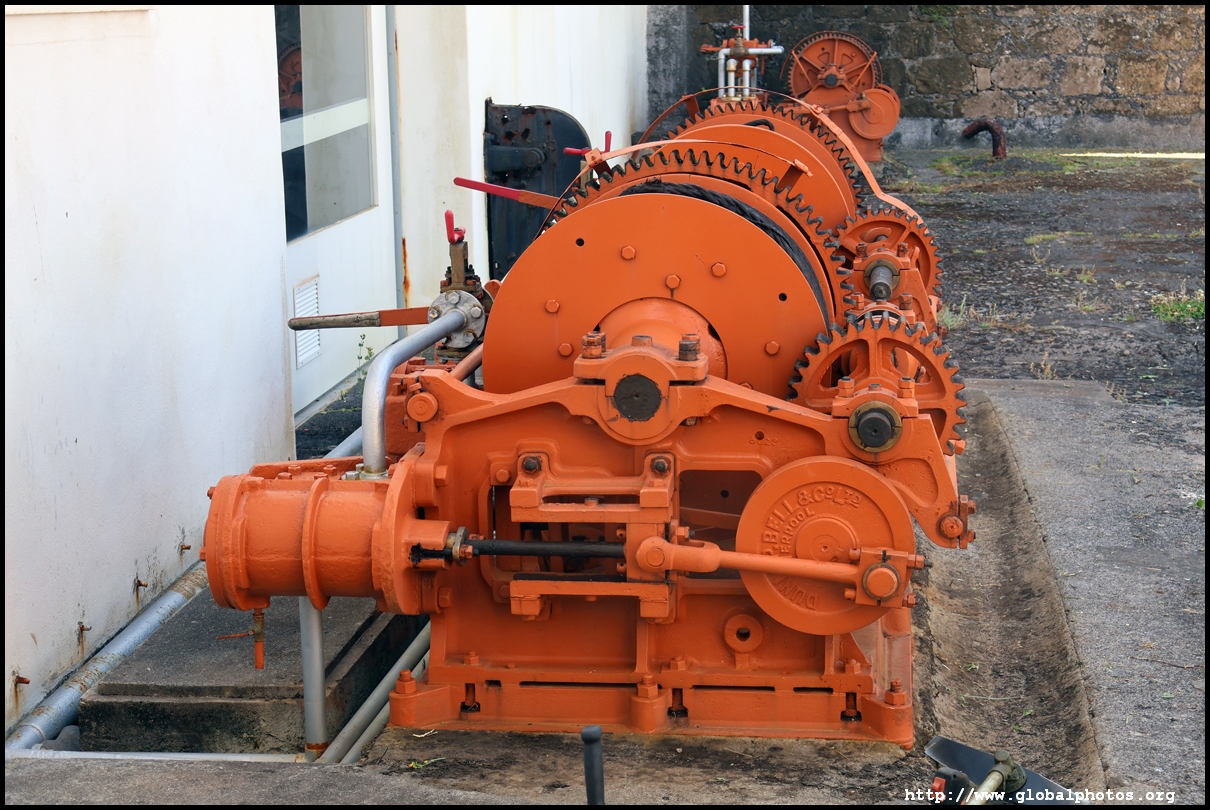

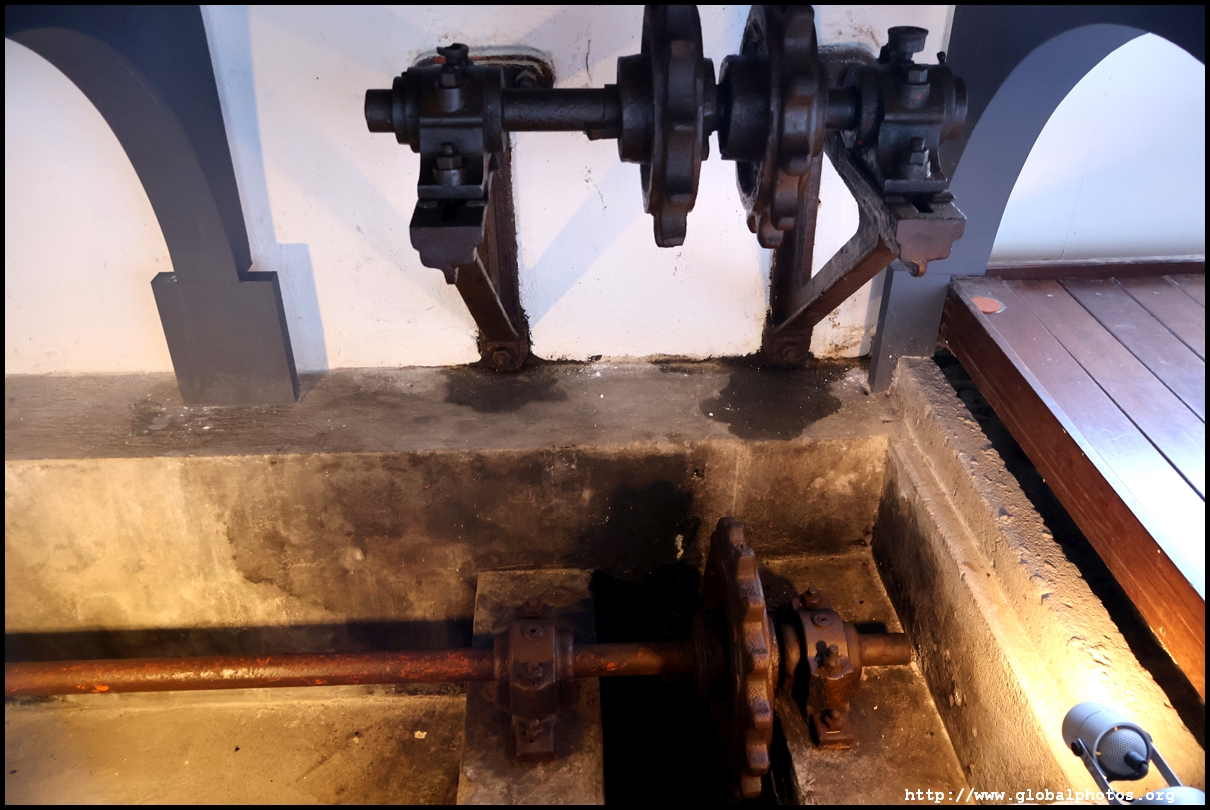

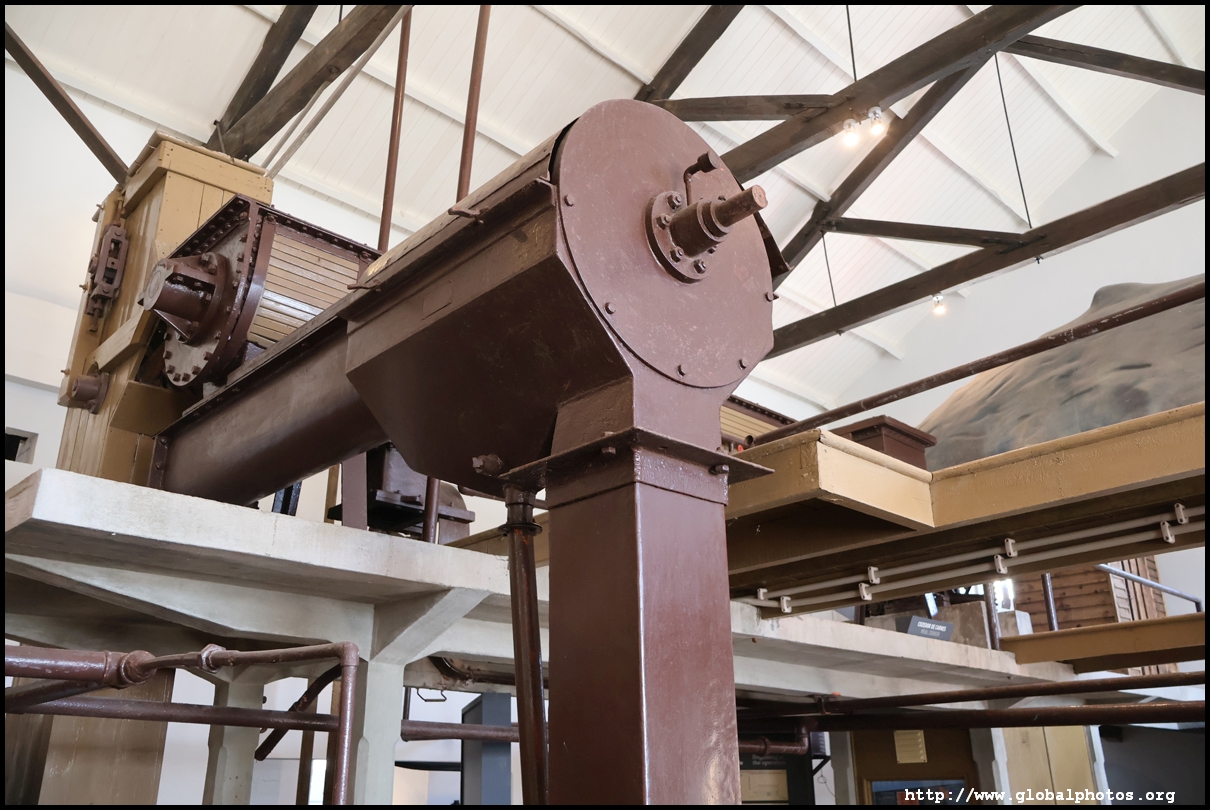

The caught whale would be hauled out of the water and up the factory ramp by winches. The head would then be cut off while workers dismembered the body, cutting off the blubber coat to put into the cookers to melt out the oil. The meat is separated and the bones cut into pieces to cook and turn into fertilizer. Blood is collected on the floor of the patio into a tank, which is mixed with lime to form a paste.

Using wood from the neighbouring island of Pico, the 2 boilers produced steam to power the factory's machinery, including cookers for blubber and bones, meat dryer, and more.

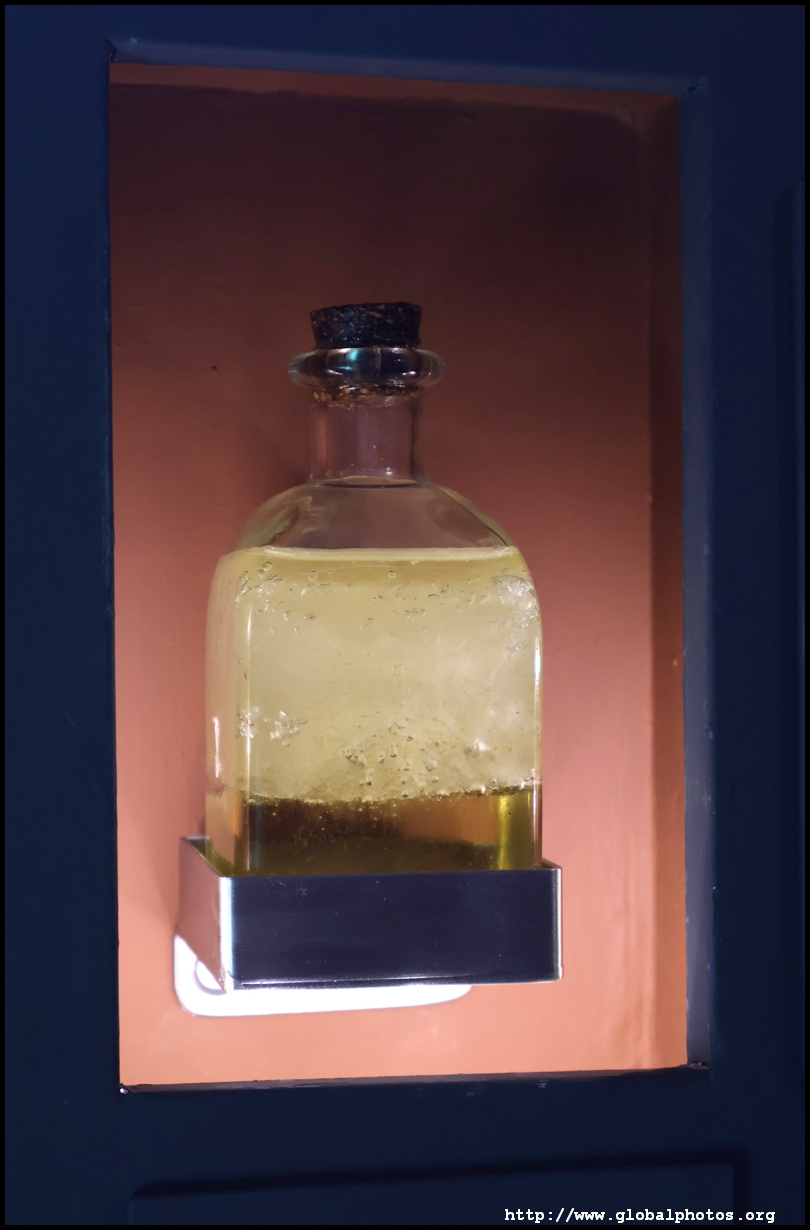

This is a sample of spermaceti extracted from a beached whale. Its skeleton is now on display upstairs.

The sperm whale's tendons had good resistance and flexibility so were used as rope substitutes.

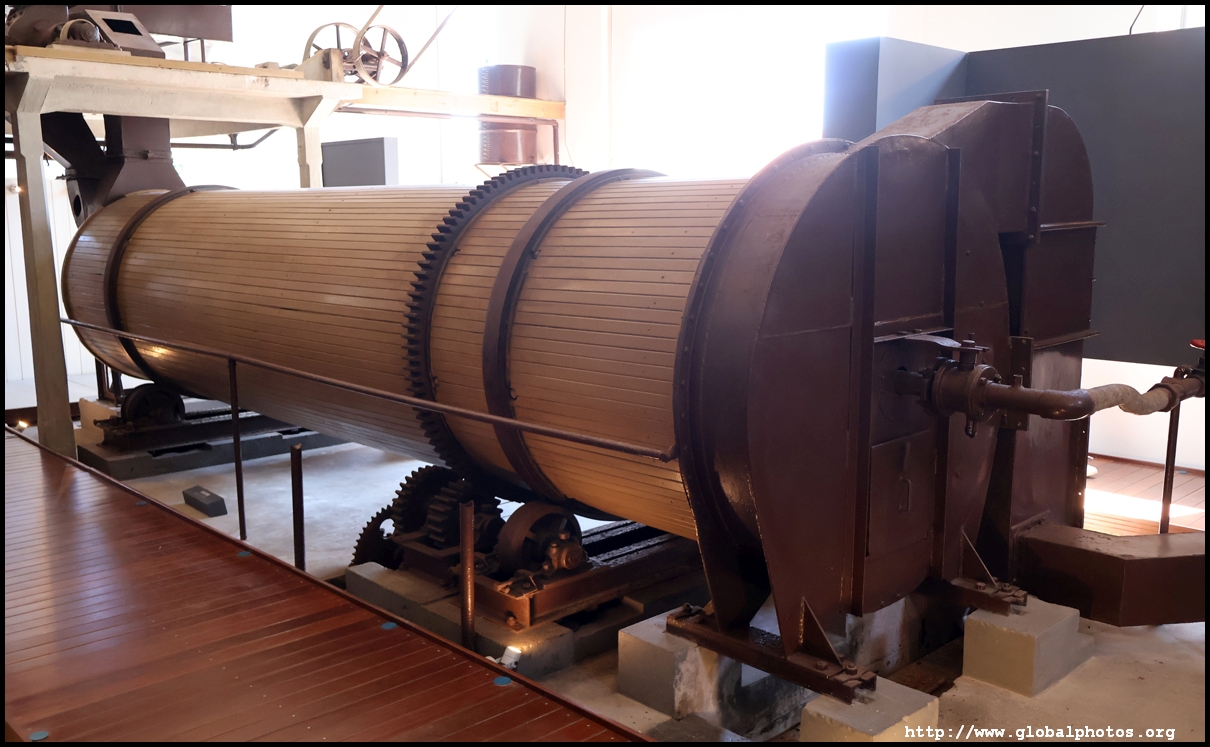

4 cookers were used to extract oil from the blubber, a process that takes about 8 hours. The melted oil goes into a storage tank underneath.

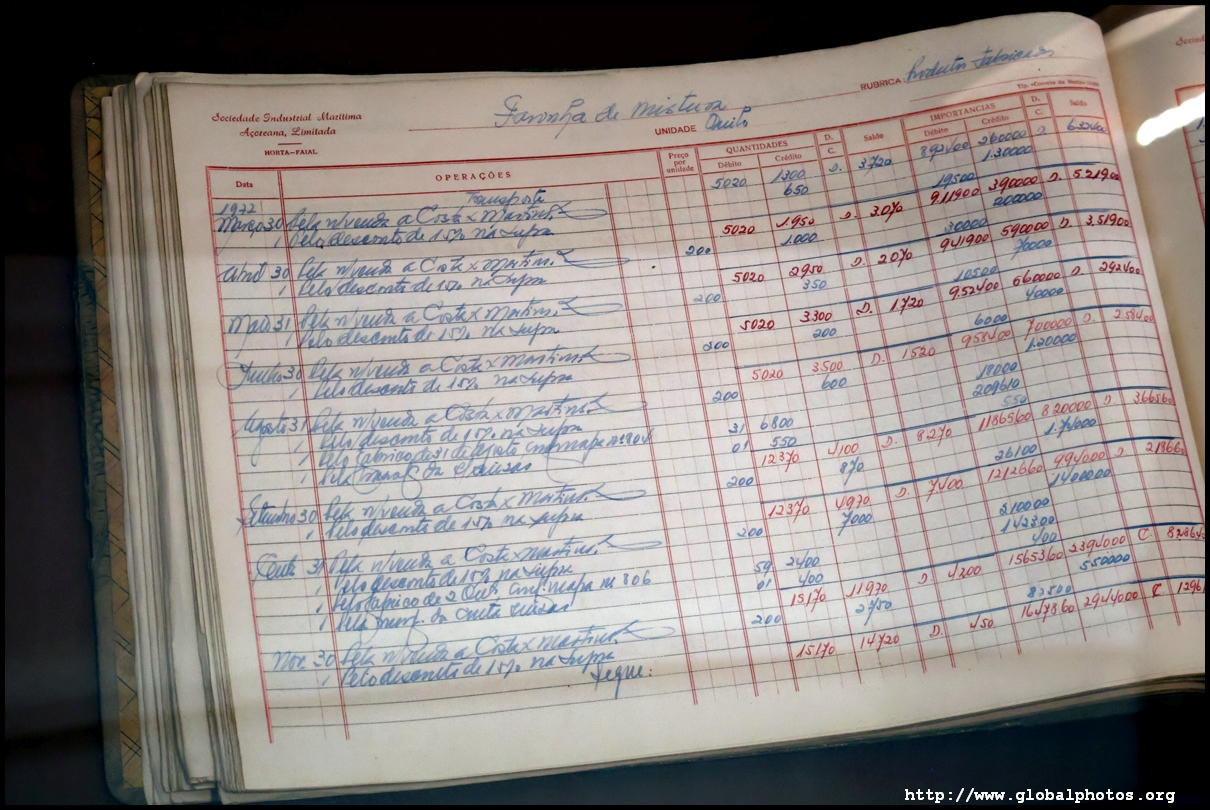

The meat is transported by wheelbarrow into the grinder, then to the cooker, drier, and finally the mill. These products are rich in proteins, so are good fertilizers.

Upstairs, there is a sperm whale skeleton on display.

While whales are not hunted in this part of the Atlantic today, tourists go whale-watching instead with high probability of catching a glimpse. Their shops are all along the marina with various tours available.